Knife Gates - Open Type

APPLICATION

For unidirectional shutoff of liquids, solids and slurries in vacuum or pressurized conveying systems.

FEATURES

- A lug type wafer design of sleek construction for low headroom mountings.

- Gate having bevelled knife edge at the bottom to cut through solid particles settled at bottom of body and achieve full closure.

- Gate fully withdrawn in the housing upon opening, thereby offering uninterrupted flow.

- Sealing achieved by means of integrally cast! welded jams pushing the gate on to the seat for a full face contact between gate and seat.

- Double / triple ply Synthetic yarn with PTFE packing glands provided with externally adjustable pusher arrangement to tighten the packing on the gate and avoid leakage through the rear of the valve.

- Non rising spindle for compact operation and increased safety.

- Gate opening indicating arrangement to find out the extent of gate opening and closing.

- Double start threaded spindle for faster opening and closing.

- Wide variety of material options - please contact us for more information.

- Seal retainer ring in soft seated ZFT-STD valve to protect valve parts against erosion and direct the flow towards centre.

SEALING OPTIONS

- Integral metal to metal seat in knife gate valve type: ZFT.

- Metal to soft seat with seal retainer ring in knife gate valve type: ZFT-STD.

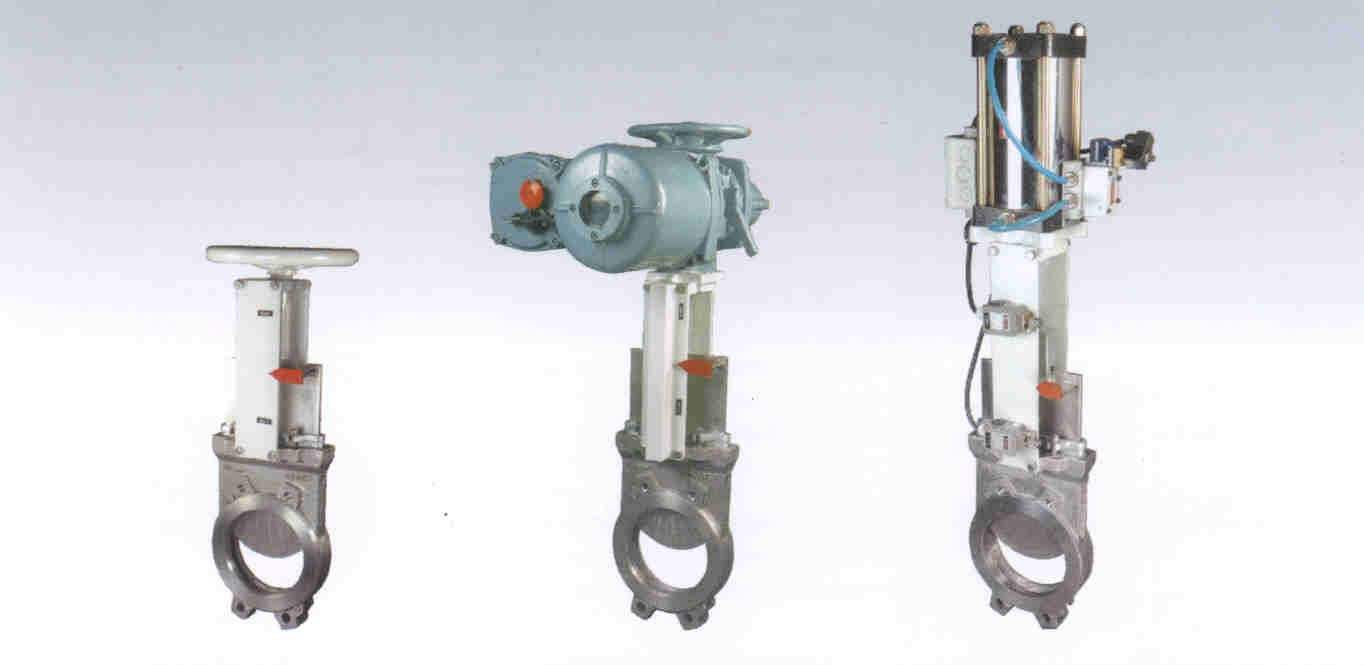

OPERATING OPTIONS

- Manual handwheel / Chain-wheel Motorised / Electro pneumatic.

FLANGE OPTIONS

- DIN PN10 / ANSI 150B 16.5 with raised face / IS: 1538-1993 with raised face. Other flange drilling options available on request.

STANDARD SIZES

- DN 50,65,80,100,125, 150,200,250,300,350,400,450,500, 600,700,800,900,1000 ,1200 mm. Sizes above DN 1200 mm can be offered on request.

LEAKAGE TESTING (Seat) .

- Conforming to MSS SP-81 for valves up to 600mm size. For higher sizes proprietary norms shall be applicable.

- For Rubber seated valve - no visible leakage.

- For Metal seated valve -40cc/minute/inch (25.4mm) of valve diameter at 40 PSI (2.8bar) across the seat.

BODY TEST PRESSURE

- 1.5 times of normal working pressure, or

- Max. 10 bar for valves up to 250mm size in cast iron body.

- Max. 6 bar for valves above 250mm & up to 600mm size in cast iron body.

- Max. 4 bars for valves above 600 mm size in cast iron body.

- Max. 10 bar for valves up to 600mm size in steel! stainless steel body.